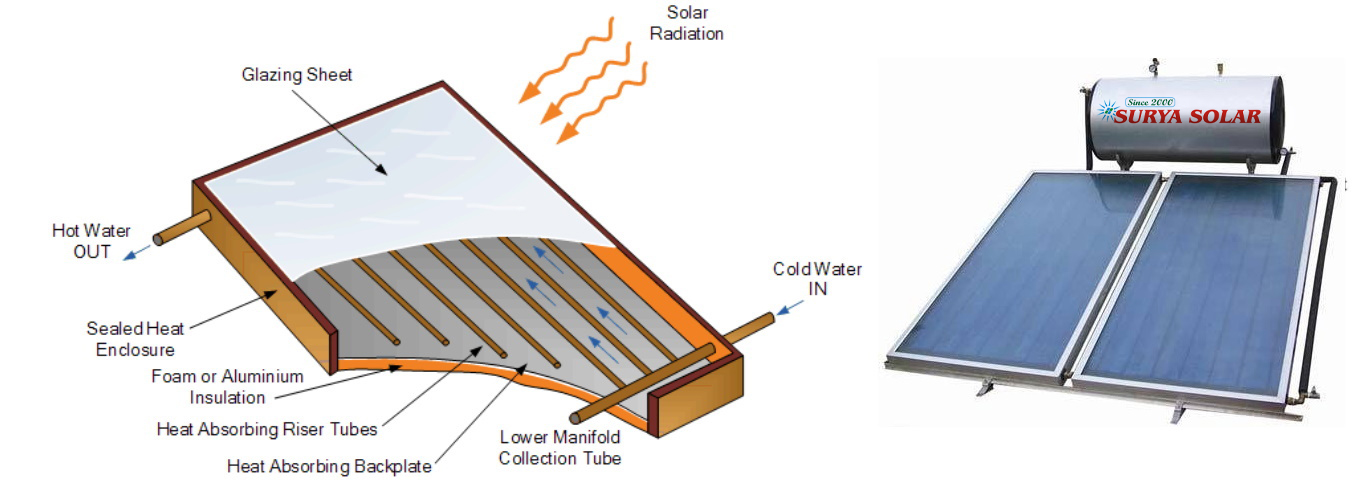

| Absorber Sheet |

Copper 32 SWG/0.19 mm thick Selectively Coated Laser Welded Nickel-Chrome coated (E.T.P. Quality) |

| Riser Tube |

Copper 12.5mm 24 SWG (+ 0.5 mm) |

| Header Tube Copper |

25 mm 22 SEG (+ 0.5 mm) |

| No. of Riser Tube |

9 Fins |

| Bonding between Riser & Absorber |

High temperature Ultrasonic Seam/Laser Welding |

| Absorber Coating |

Selective coating absorbity 0.95+ 0.02 Emmissivity = 0.10 +0.02 |

| Front Glazing |

Toughen Glass 4 mm thickness Transparency 95% and above |

| Back Insulation |

50 mm thick Rock wool slab density of 48 Kg/M3 with Aluminum foil |

| Gasket |

EPDM Rubber Grommets and Glass Beeding |

| Collector Box |

Jindal/JCW ms sheet, extruded channel backed by a sheet of 22 SWG |

| Header Inlet & outlet jacket |

Brass flanges 62 mm dia |

| Collector stands and legs |

M.S. “L” Angle with enamel coated |

| Support top glazing |

Glass retaining aluminum beeding 1.6 mm |

| Collector Box welding |

TIG welding |

| Insulation |

Rock Wool/PUF |

| Fosterers |

S.S.Screws and Bolt Nuts |

| Collector Sealant |

Silicon base |

| Hot Water storage tank |

Stainless Steel 304 grade (food grade) plasma TIG Welded Tank /CR with Coating /Copper Tank |

| Insulation |

150 mm rock wool (compressed 100mm) 48 kg/m3 density (or)PUF insulation |

| Outer Cladding |

Powder coated optional SS 302 stainless steel |

| Screws and Fasteners |

Stainless Steel |

| Pipes and fittings for internal |

SS fittings “B” class, IS Standard |

| Pipes and fittings for external |

SS fittings “B” class, IS Standard |

| Temperature Gauge |

NIL |

| Electrical Backup |

As per the electrical power sanctioned, each 200 LPD 2Kwh given.(Optional) |

| Supporting structural stand |

MS Channels/angles of suitable size with enamel coated |